Overview

Design considerations

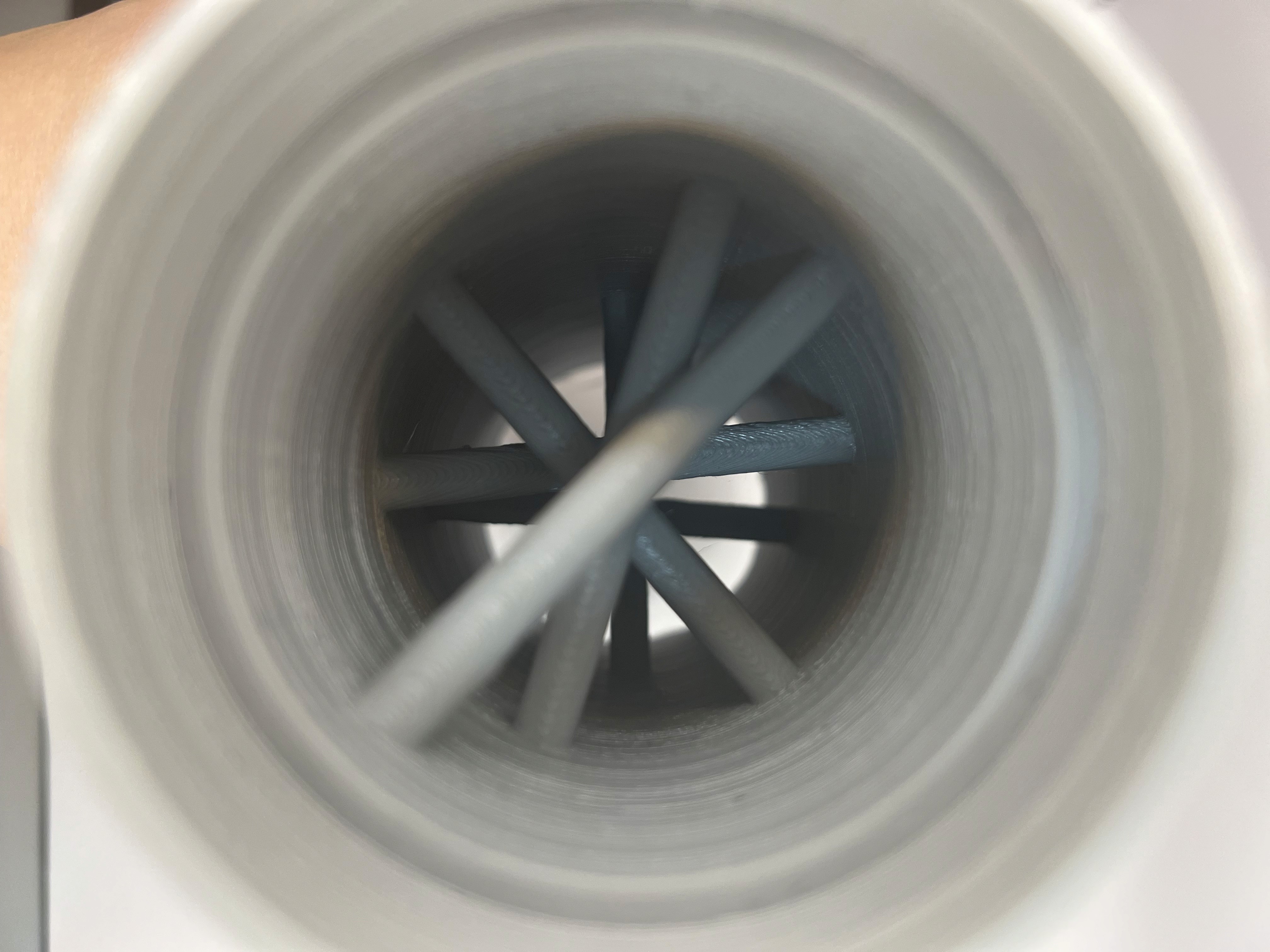

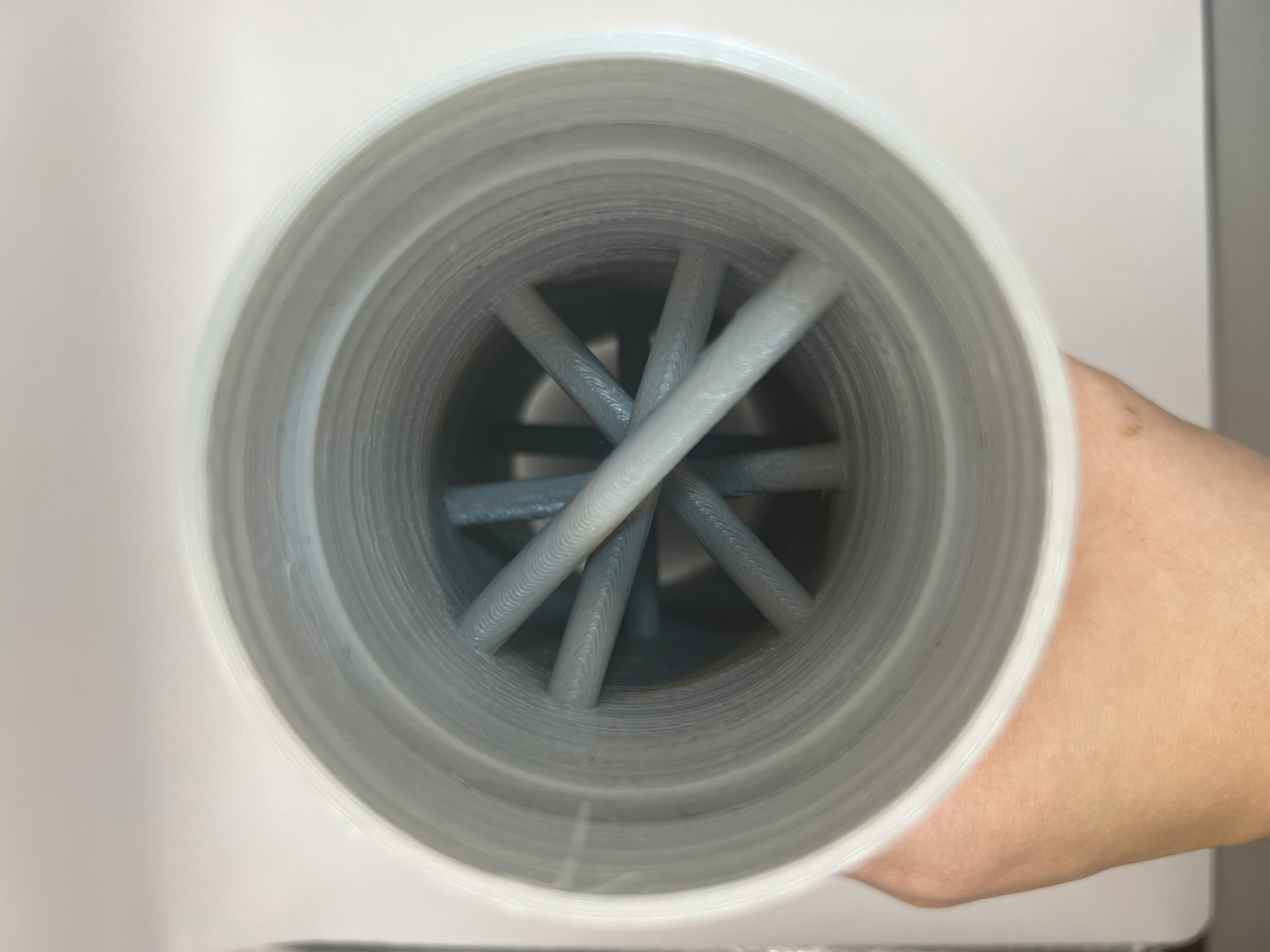

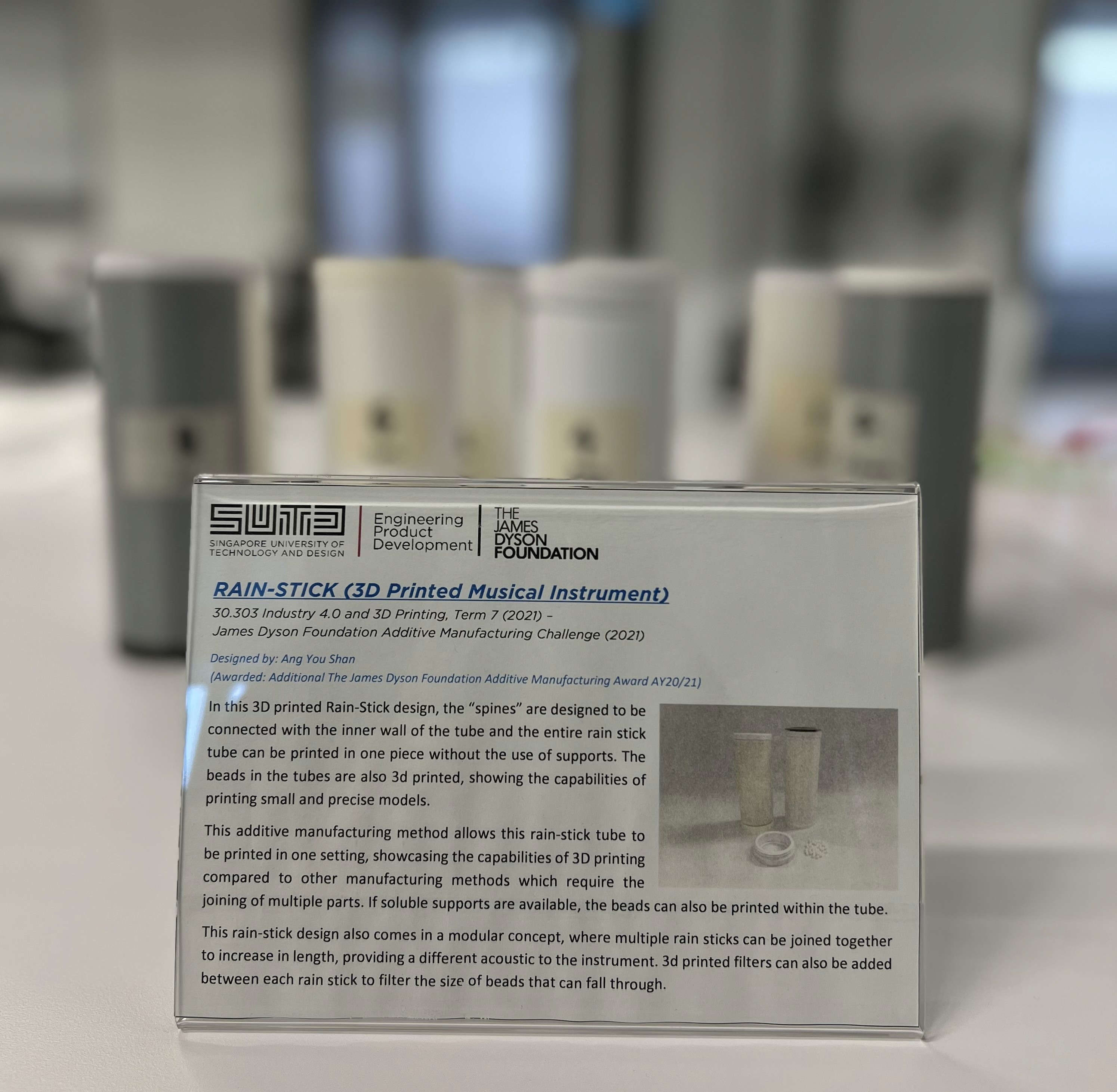

Traditionally, a rainstick is a long, hollow tube partially filled with small pebbles, rice, dried beans, or other hard granular matter that has small pins or thorns arranged helically on its inside surface. When the stick is upended, the pebbles fall to the other end of the tube, bouncing off the internal protrusions to create a sound reminiscent of falling rain.

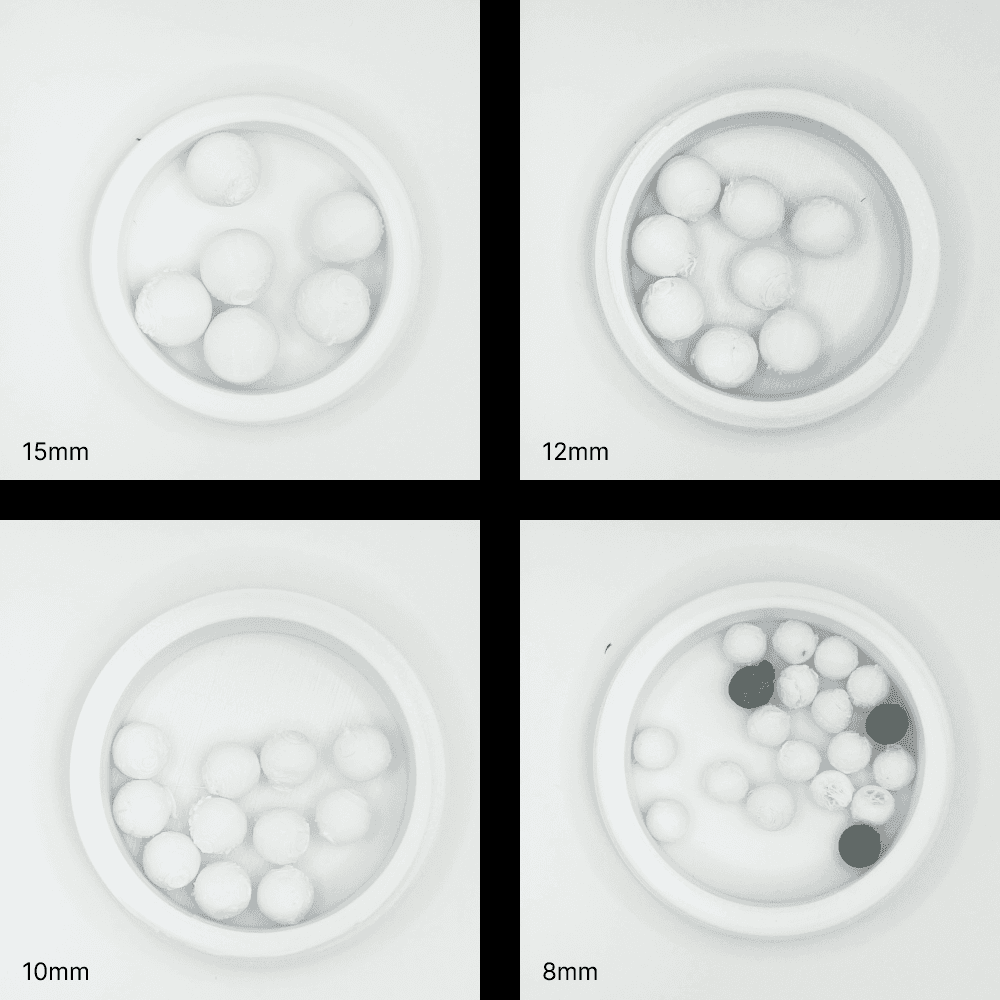

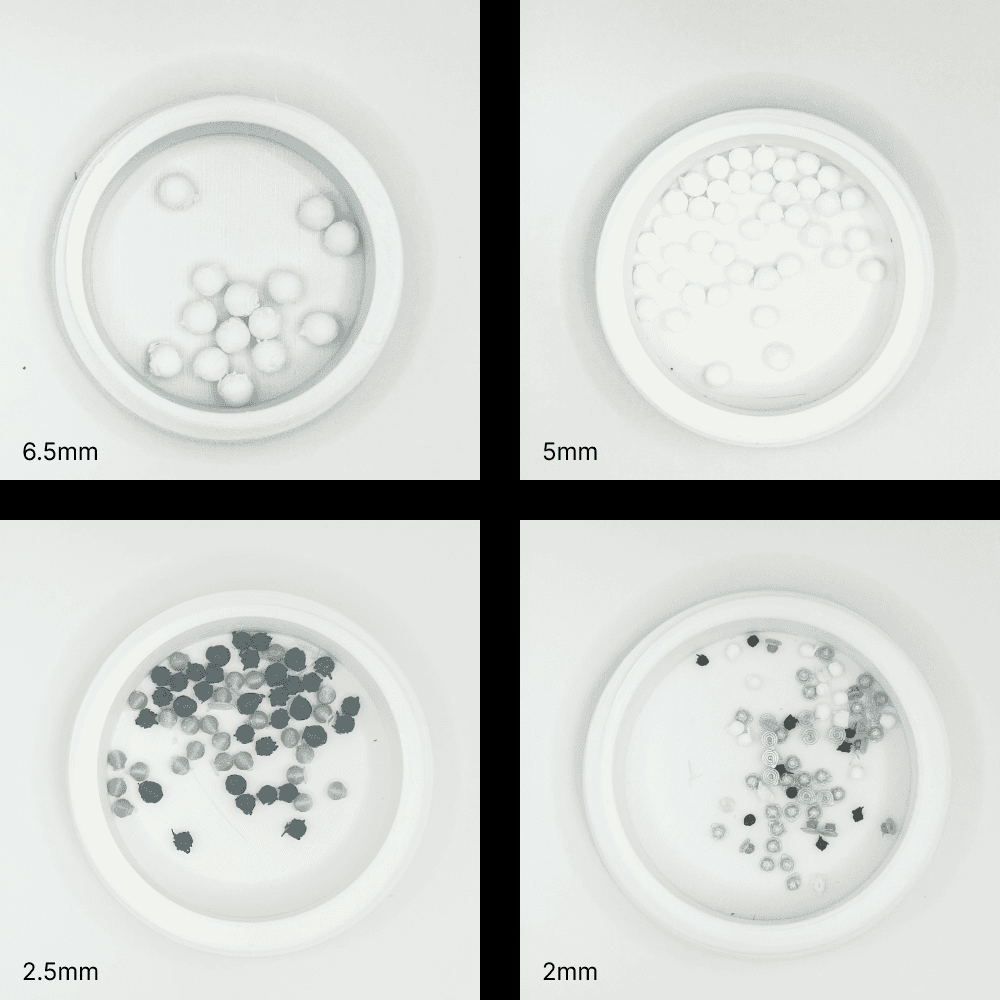

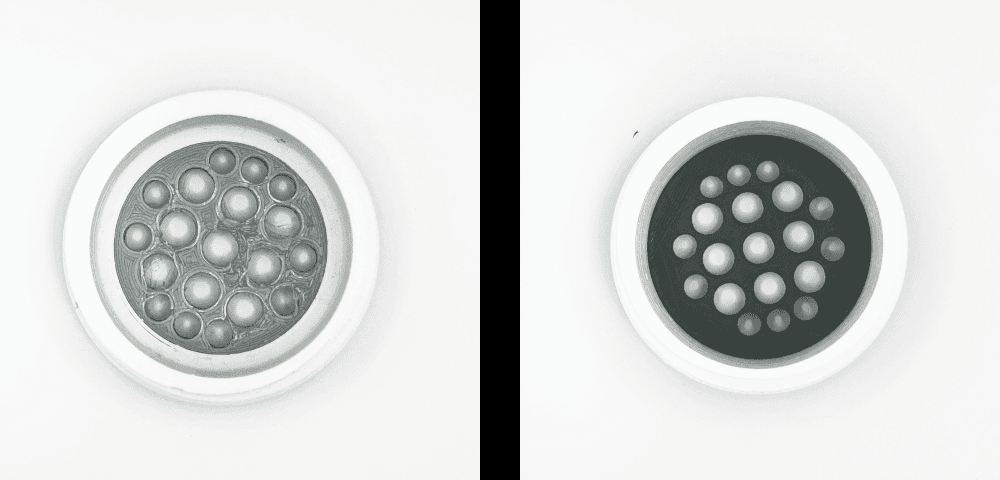

In my rainstick, I explored 8 different sizes of beads to mimic the different types of beads that a rainstick is typically filled with. The splines in the inner structure are also mimicking the thorns of a cactus that is found in a traditional rainstick.

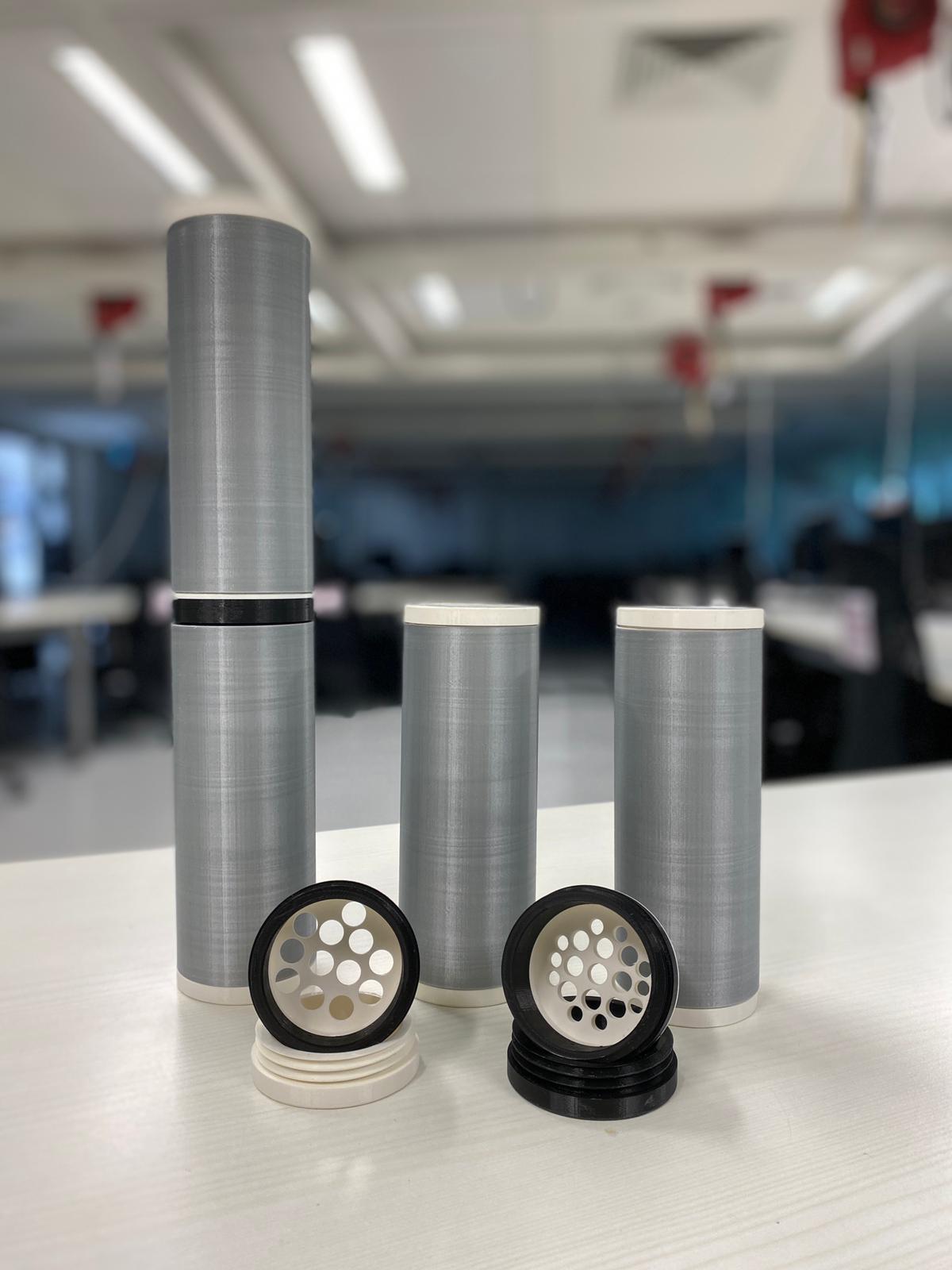

Elevating my exploration, I've transformed this instrument into a modular setup. Utilizing filters, one can connect multiple tubes to create varying lengths of the rainstick, producing distinct acoustics.

Additionally, the filters control the bead sizes that can fall through, resulting in unique sound combinations.